Expertise

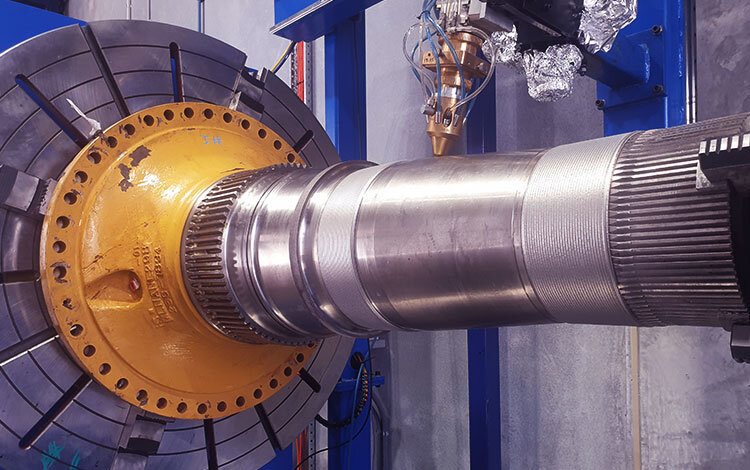

Metal Spray

Our Twin Wire Arc Spray process offers cost effective repair for damaged or worn parts. Most commonly repaired areas include: bearings, seal journals and hosing bores. We follow a strict process for the preparation and application of materials. The advantage of the TWAS process is the minimal temperature that is used during application. This ensures you are not affecting the parent material with a large heat affected zone as you would with a standard welding process. Currently we have two Metal Spray rooms in use, both with turntables.

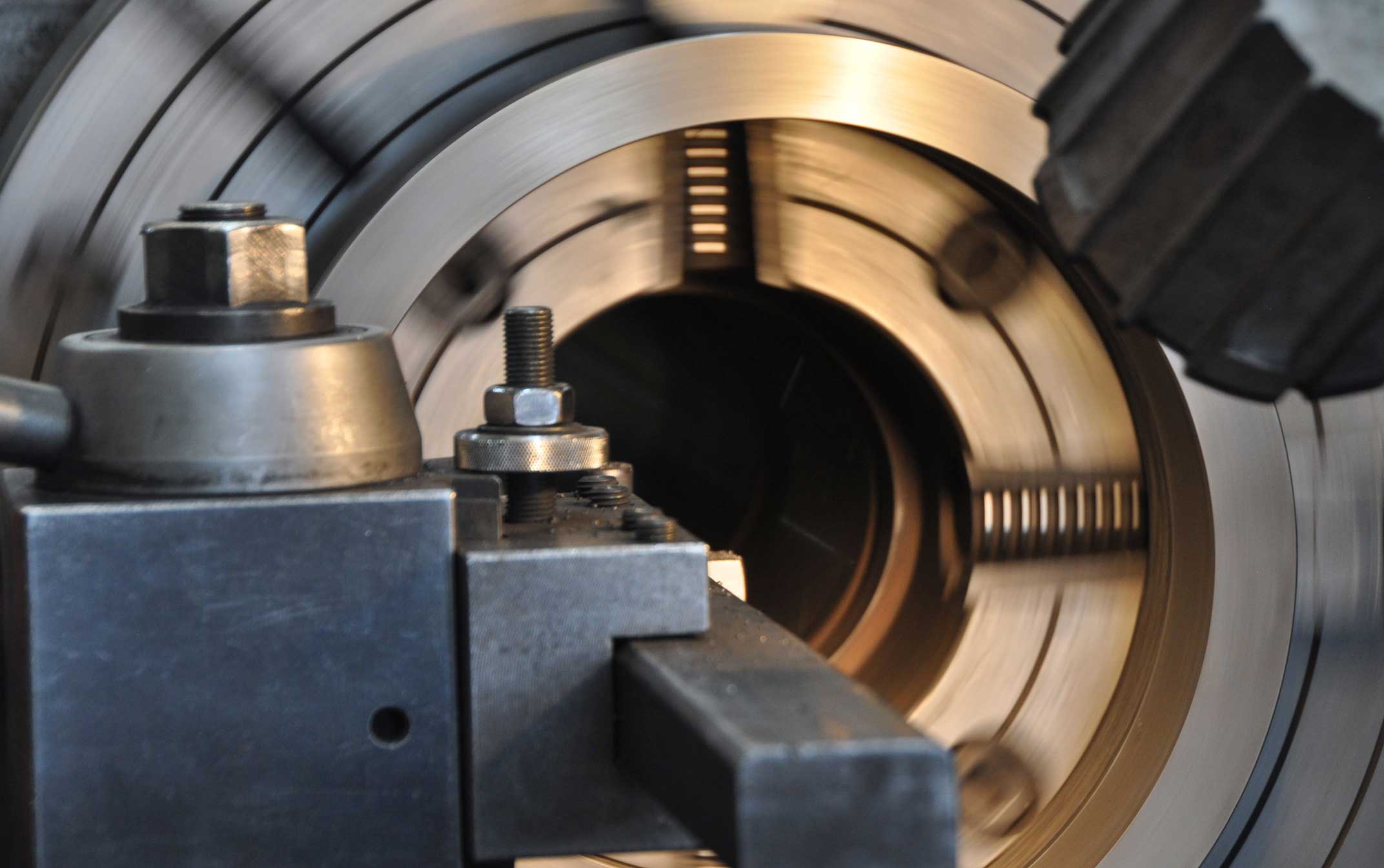

Machining

With our 35 years in the component repair industry we have built a substantial fleet of machines that can handle the repairs that our customers require. These machines include but are not limited to: 3 Separate Vertical Borers, a Matrix Machining Centre, a Horizontal Borer, a Milling Machine, 5 different Lathes, Radial Grinders, Radial Arm Drills and two Overhead Cranes with capacities of over 6.3T. Our machines are ideal for the internal or external machining of Wheel Hubs, Seal Rings, Torque Tubes and Flingers. All of our machinery is regularly updated and maintained to ensure that our products are to the highest standard and most cost effective on the market.

Welding

We offer an extensive range of welding repair options for our customers. Each weld is carefully carried out to ensure high stability. We operate in: Arc Welding, MIG, TIG and Oxy-Acetylene. We use a Fronius ID Welder for our welding purposes.

We work with a 3rd party NDT supplier that uses our onsite dark room to independently test and report on incoming goods and post welding to confirm the status of the part.

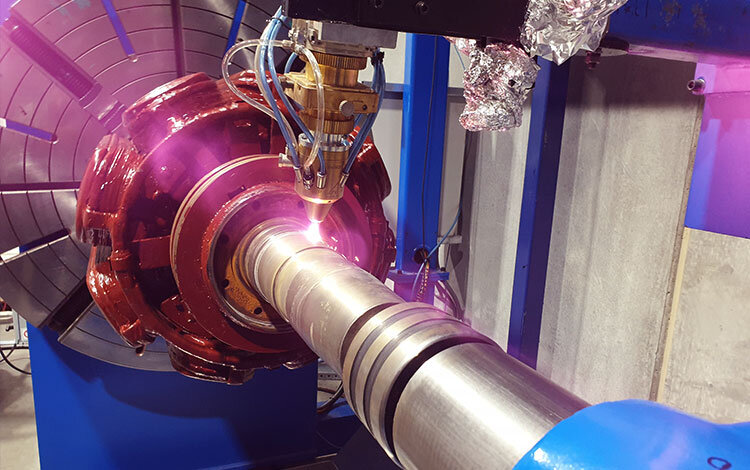

Laser Cladding

Our state of the art Laser Cladding system enables us to offer a premium quality repair to worn parts. Laser Cladding offers a metallurgical bond to the substrate, this is what sets it apart from TWAS, HVOF & HVAF. Along with this being a metallurgical bond it creates virtually no heat affected zone unlike traditional Welding or Sub-Arc Welding processes. There is a large variety of materials that can be applied depending on the application of the item and your requirements.